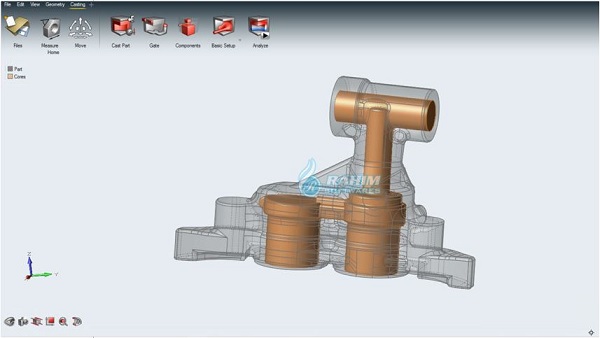

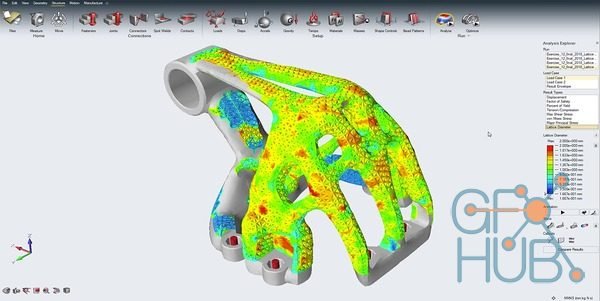

Guided process templates offer 5 easy steps to simulate Gravity Die, Gravity Sand, Investment, High Pressure, Low Pressure Die Casting and Tilt Pouring. Right from early design phase, users can visualize typical casting defects such as air entrapment, shrinkage porosity, cold shuts, mold degradation and rectify them avoiding costly downstream corrections. It is the only tool that caters to beginners and experts alike, from product designers to foundry engineers. Altair serves more than 5,000 customers across broad industry segments.Altair Inspire Cast (formerly Click2Cast) software is a fast, easy, accurate and affordable casting simulation environment focused on creating high quality components with increased profitability through a highly intuitive user experience. With more than 2,000 employees, Altair is headquartered in Troy, Michigan, USA and operates 71 offices throughout 24 countries. Our broad portfolio of simulation technology and patented units-based software licensing model enable Simulation-Driven Innovation for our customers. And PolyNURBS makes it easy to post-optimize your model to get a workable model.Īltair transforms design and decision making by applying simulation, machine learning and optimization throughout product life cycles. Models made with 3D printing give designers greater freedom, but when a topologically optimized product is produced by a casting process, for example, the system looks for molding skews. Optimization can take into account the manufacturing technology with which the product will be made. With the latest version of the software, you can easily create optimized grid or mixed solid grid structures that can then be evaluated within the software or even exported in.

Inspire’s main strength lies in topology and topographic optimization, which utilizes Altair’s market-leading OptiStruct technology to generate and examine plans. With the Inspire platform, users can quickly and easily create new constructs and analyze them with linear, non-linear, and dynamic simulation to produce the right product for the first time. One of its specialties is the ConstructionTree model history feature. Studio is suitable for creating organic surfaces, parametric body models and NURBS based surface and body models. We can use our initial sketches, alternate render styles, and create real-time photorealistic renderings. Inspire Studio speeds up the design of free-form surfaces.

0 kommentar(er)

0 kommentar(er)